FDM 3D printing background

1.Basic knowledge

FDM(Fused deposition modeling) ,also called FFF(Fused filament fabrication or filament freeform fabrication). It was developed by S.cott Crump , co-found of Stratasys in 1988.

2. Customer FDM 3D printing

It is very popular even somebody use FDM 3D printing replace all 3D printing. The reason of customer FDM 3D printing is following:

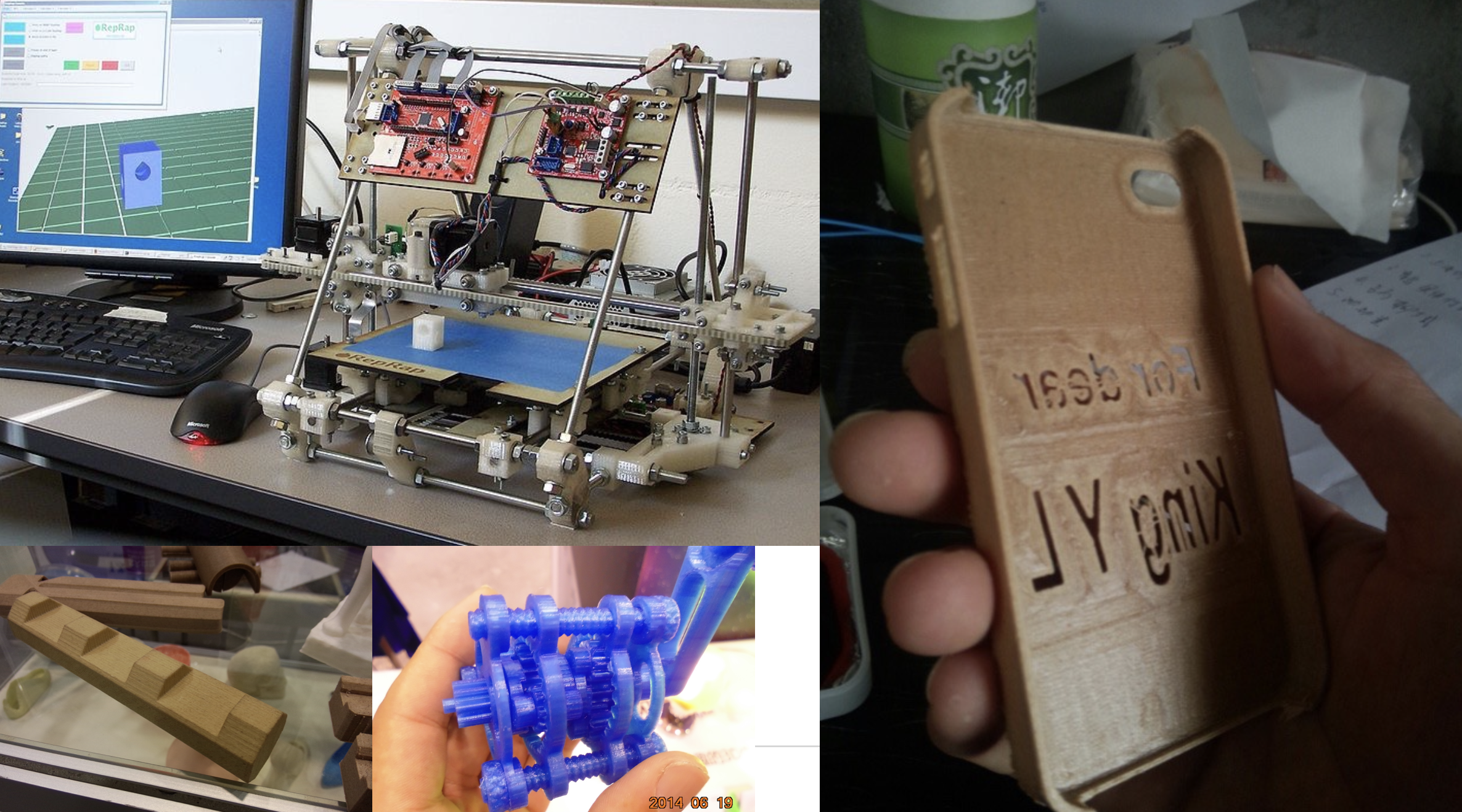

- Open source: FDM 3D printing is open source from 2005 in England. RepRap project(short for replicating rapid prototyper) open source all detail according to GNU General Public License

(reference from RepRap)

it push forward the develop and popular in maker community. Because RepRap is humanity's first general-purpose self-replicating manufacturing machine. Makers can easy to build their own FDM 3D printing with the basic technology.

(reference from RepRap)

it push forward the develop and popular in maker community. Because RepRap is humanity's first general-purpose self-replicating manufacturing machine. Makers can easy to build their own FDM 3D printing with the basic technology. - Easy operate:open source model,software setting, filament prepare, machine check and operation are easy to learn.

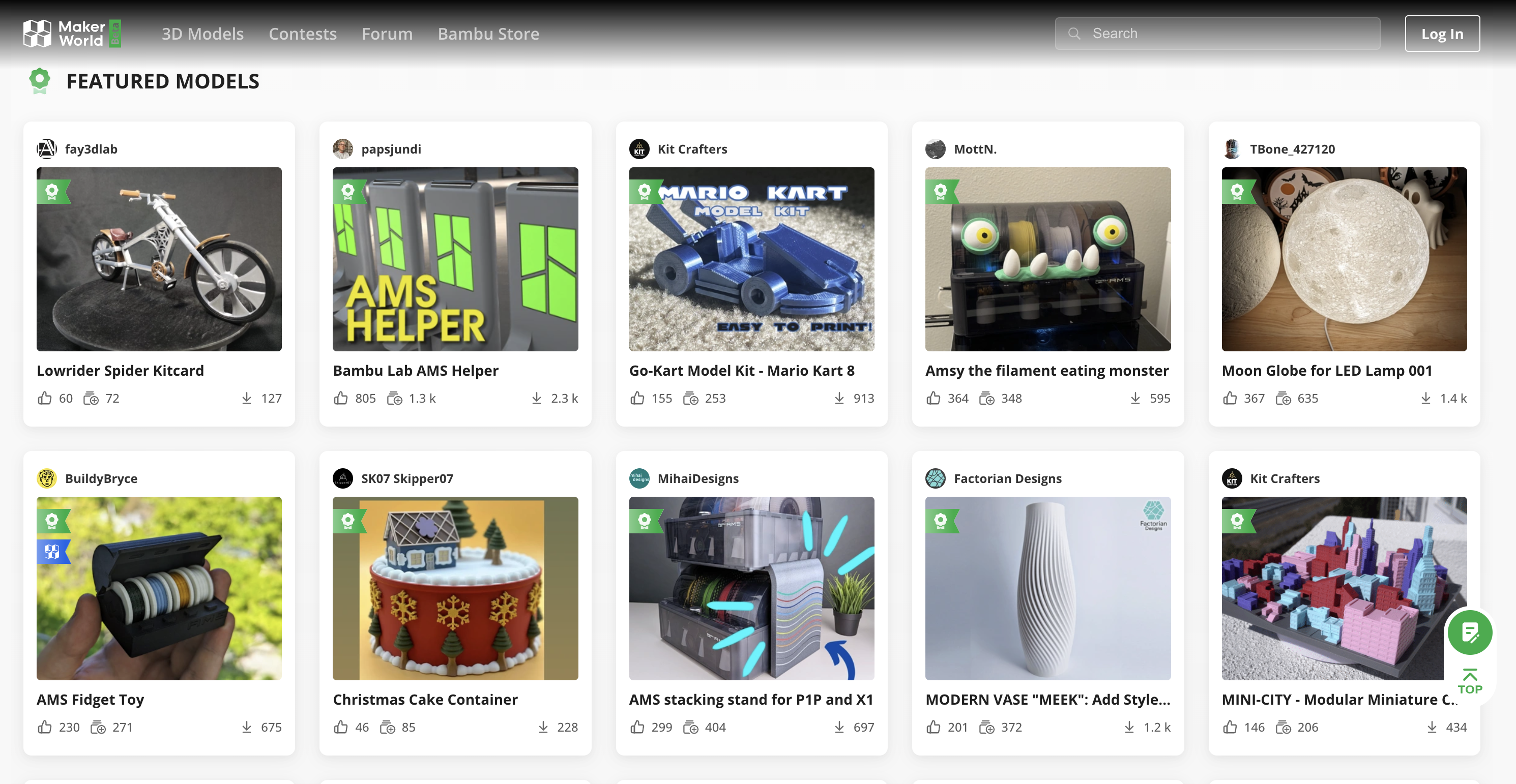

- Makerbot build Thingiverse which is the biggest open source 3D printing model community in the world. Maker can download the model they need. It lows down the hardness in design.

- Ultimaker provide Cura which is easy to set 3D printing parameter

- Bambambulab build MakerWorld

- Makerbot build Thingiverse which is the biggest open source 3D printing model community in the world. Maker can download the model they need. It lows down the hardness in design.

* Filament prepare: We can load material according to the flowing pictures:

- low cost :Because of "Open Source", almost every component of customer FDM 3D printing is standard part and we can purchase them online (Taobao for reference ). Maker and 3D printing company can design their own machine and then purchase most of components in market.

Obviously, maker ,design for their prototype and maker education would use customer FDM 3D printing.

3.Industry FDM 3D printing

But industry need more. We can find some industry FDM 3D printing companys , for example

- Stratasys FDM has many industry materials(ABS, Nylon,TPU, Carbon Fiber……) which can meet high strength and reliable industry requirement.

Desktop Metal: Powered by Single Pass Jetting™ (SPJ™), the Production System features bi-directional printing where all steps of the print process—powder deposition, spreading, compacting, ballistic suppression, and binder jet printing—are applied with each pass over the build area. Whenever there is movement, there is printing—making it the fastest way to print complex metal parts.

Markforged: With Markforged 3D printers user can economically print with advanced materials including nylon, chopped carbon fiber, reinforced continuous fiber, and metal.

4.The principle of FDM

There are 2 kinds of FDM 3D printing

Cartesian(left one:Red): 3 motor control x,y,z axis and the machine is stable;

Delta(Right one: Blue): The key design feature is the use of parallelograms in the arms, which maintains the orientation of the end effector which restrict the movement of the end platform to pure translation, i.e. only movement in the X, Y or Z direction. The advantage of delta is fast and cost is low.

Basic principle :

There are 2 kinds of FDM 3D printing

Cartesian(left one:Red): 3 motor control x,y,z axis and the machine is stable;

Delta(Right one: Blue): The key design feature is the use of parallelograms in the arms, which maintains the orientation of the end effector which restrict the movement of the end platform to pure translation, i.e. only movement in the X, Y or Z direction. The advantage of delta is fast and cost is low.

Basic principle :

- First step motor control drive wheel and push forward filament into machine's hot nozzle;

- Hot nozzle heat filament and liquifier it. Then liquid mater drop down because of gravity.

- 3 motor control x,y,z distance;

- Material drop down to certain position.

- Build model one layer by one layer

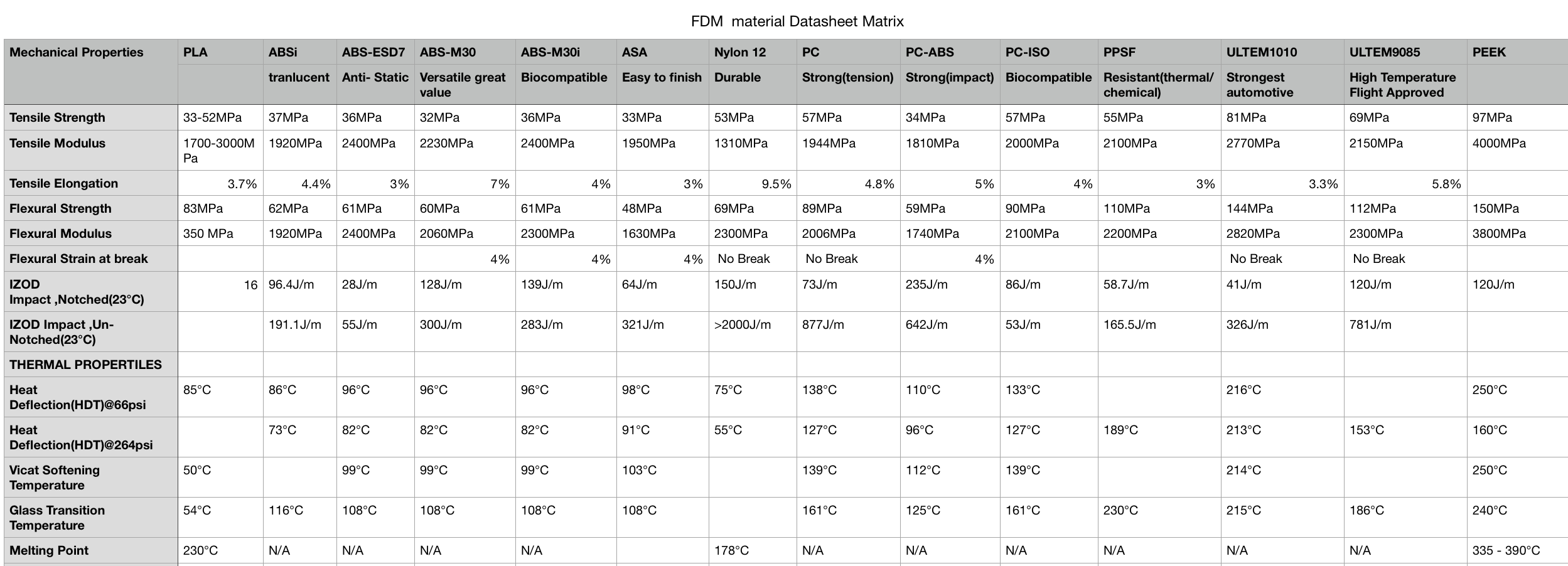

5. Material

Obviously, ABS and PLA are most popular in FDM 3D printing. They have different features. For ABS, the mechanical properties is better than PLA and easy to post polish. But the model is easy to bend at the begging of printing. In addition when the machine in printing, ABS waste dust diffuse which is bad to body. So we will find most of FDM machine for ABS would enclose, need hot bed for platform. For PLA, the material is health to body and could connect with platform to avoid bending.But it is a little hard to post polish. In addition, we can provide many different kind of industry materials as following

reference from 3D Hubs

we can find the detail introduction in this link about how to do this test

6. Application

6.1. Education

3D printing especial FDM 3D printing is one of the tool for STEM education and maker education. With the tool of 3D printing, Students can learn, design, make, test their structure quickly to verify their concept. In addition, FDM 3D printing is one of the efficient method to make the prototype.

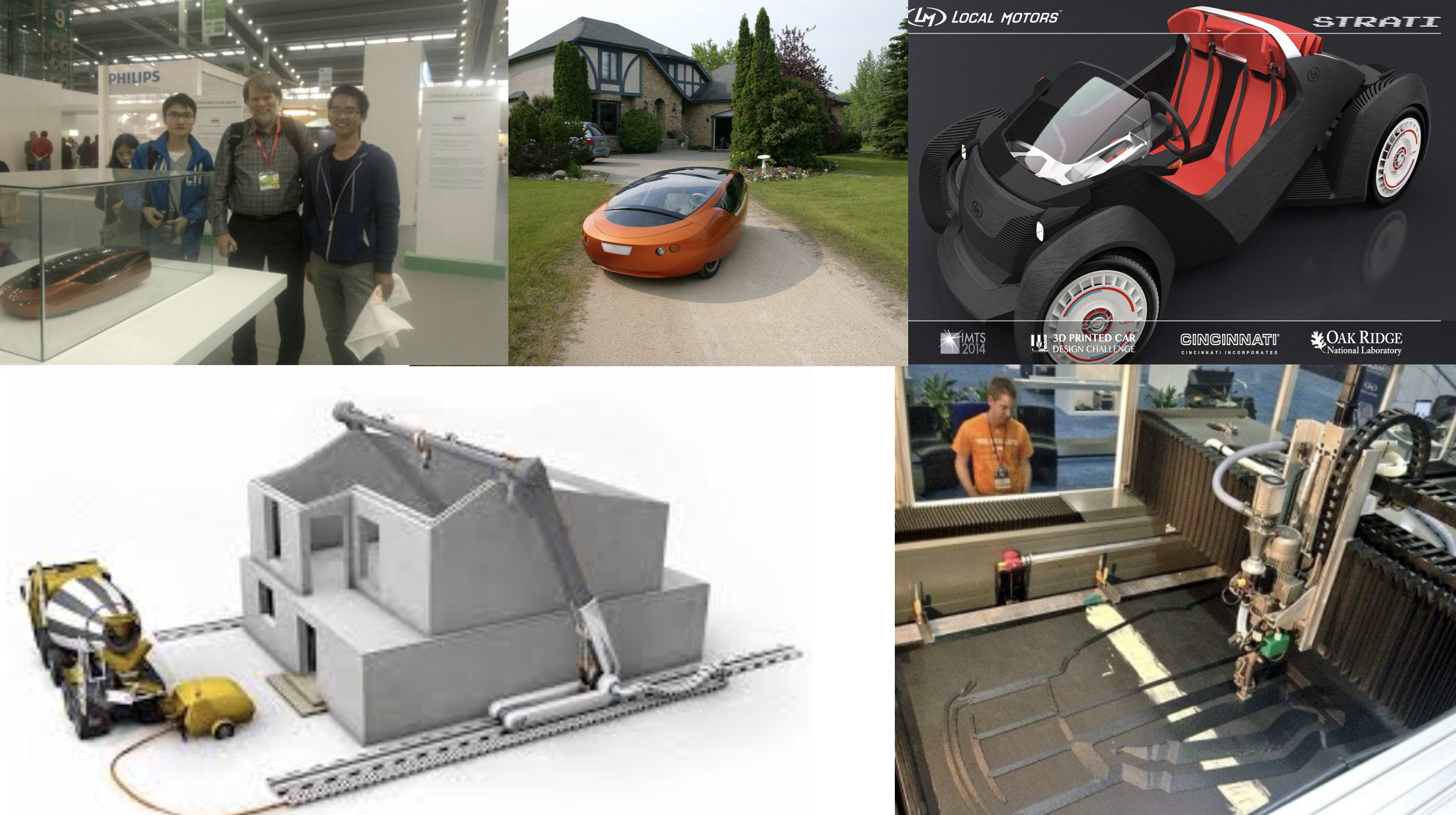

6.2. Maker project

For maker project, they want to process quick and low cost. Before the popular of FDM 3D printing, hand working( but can't make sure the precision and cost time) or Industrial processing(the cost is high ) can support maker's project, obviously it's not good choice.

RepRap project is maker project. Because of the gene, I think FDM 3D printing born for maker. Maker can design their own structure and then print it in machine high efficient and low cost. Then maker can assemble and test in their own project. Some makers even can use FDM model in small batch product and we can find many in Kickstart.

RepRap project is maker project. Because of the gene, I think FDM 3D printing born for maker. Maker can design their own structure and then print it in machine high efficient and low cost. Then maker can assemble and test in their own project. Some makers even can use FDM model in small batch product and we can find many in Kickstart.

Now some FDM 3D printing even can print industry material for function part such as : Nylon,PEEK, Carbon fiber,TPU.

6.3. Prototype test

The price of CNC and other 3D printing is very high, in addition they need experience worker to run the machine. So most of company would send their design to vendor to process, but it need time.

In industry, FDM 3D printing is good choice for designer's prototype test. Company could purchase one then test their design by themselves. If there is any problem, they can redesign and make it again. For make it can save many time .

6.4. Custom product/industry useage

For some designer ,artist, they want to design unique product. Some of them would use 3D printing to custom some detail.