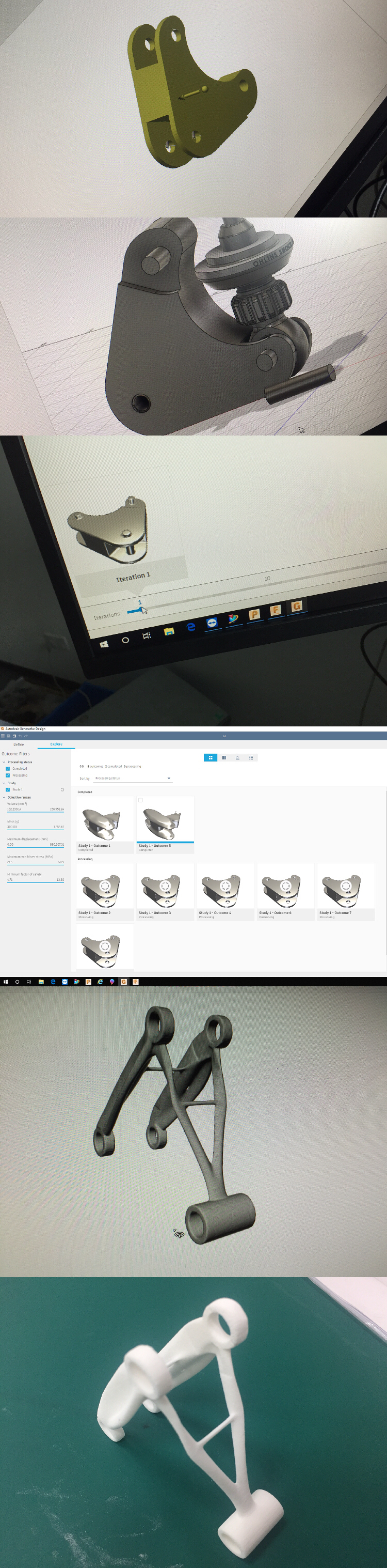

3D printing background

1.Basic knowledge

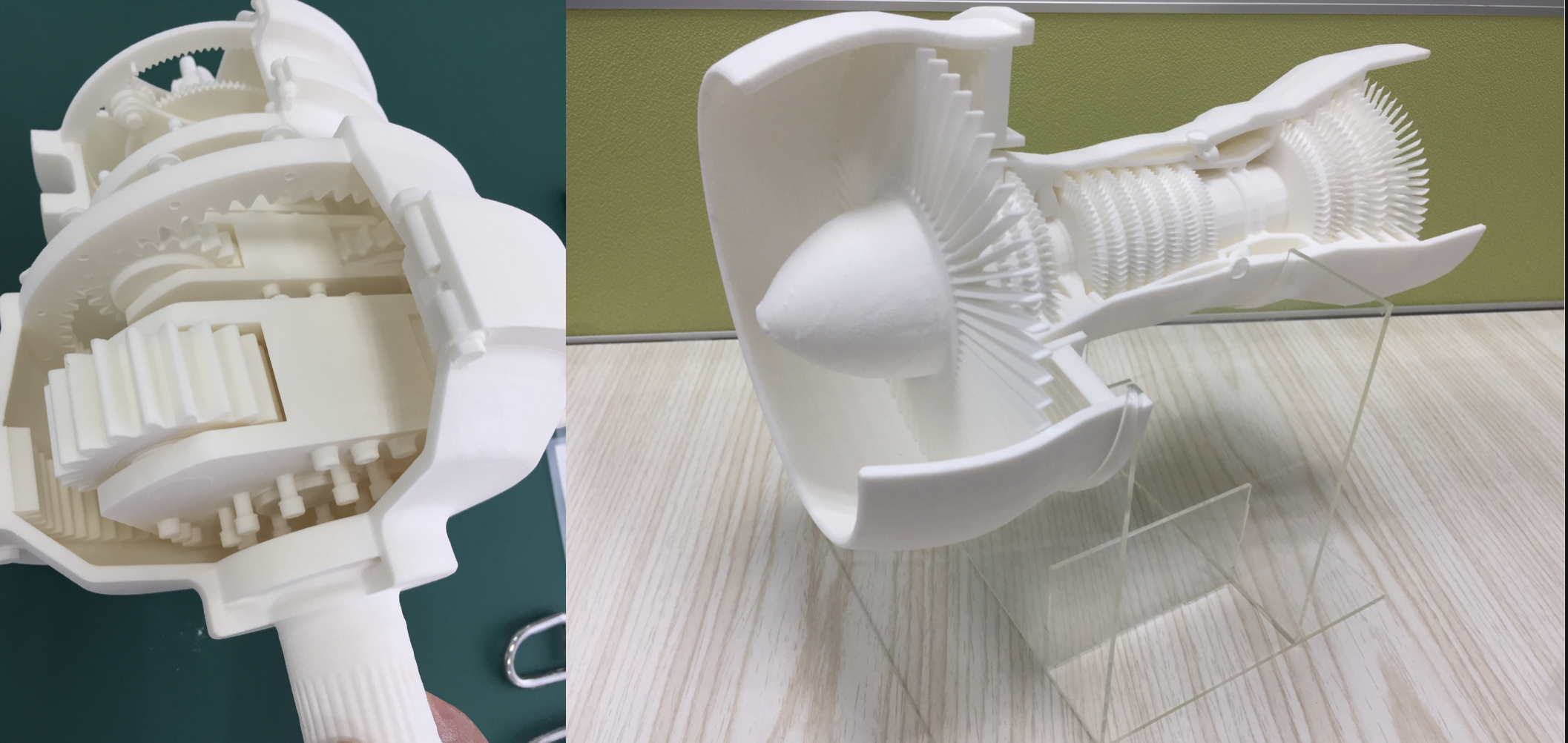

3D printing technology (also called Rapid Prototyping) is an additive computer controlled processes that builds part inside a machine, layer by layer, using a variety of materials and processes. It's cool that 3D printing can output physical prototypes directly from the computer. The invention time is similar with CNC , in the late 1980s .Although it is not so popular with CNC ,it transformed our thinking about prototype making. This ability has great push forward product development. In addition, 3D printing has special advantage in complex model, inner flow channel, cavity, thin wall, and rib which are difficult to make by any other method. The first technology of 3D printing called SLA(Stereolithography Apparatus)found by Chuck Hull

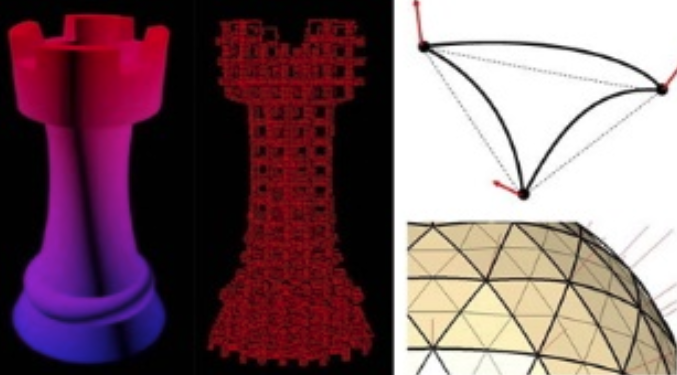

Normally,we would use stl formate to save data ,which covered with triangle surface.

2.Work flow

The basic principle is the following:

Reference from my 3dconcepts Watch the video from YouTuBe to get more detail.

3. Different kinds of 3D printing

According to ISO/ASTM 52900:2015(en)Additive manufacturing — General principles — Terminology, we can find the following Process categories

Reference from 3D hubs

Reference from 3D hubs

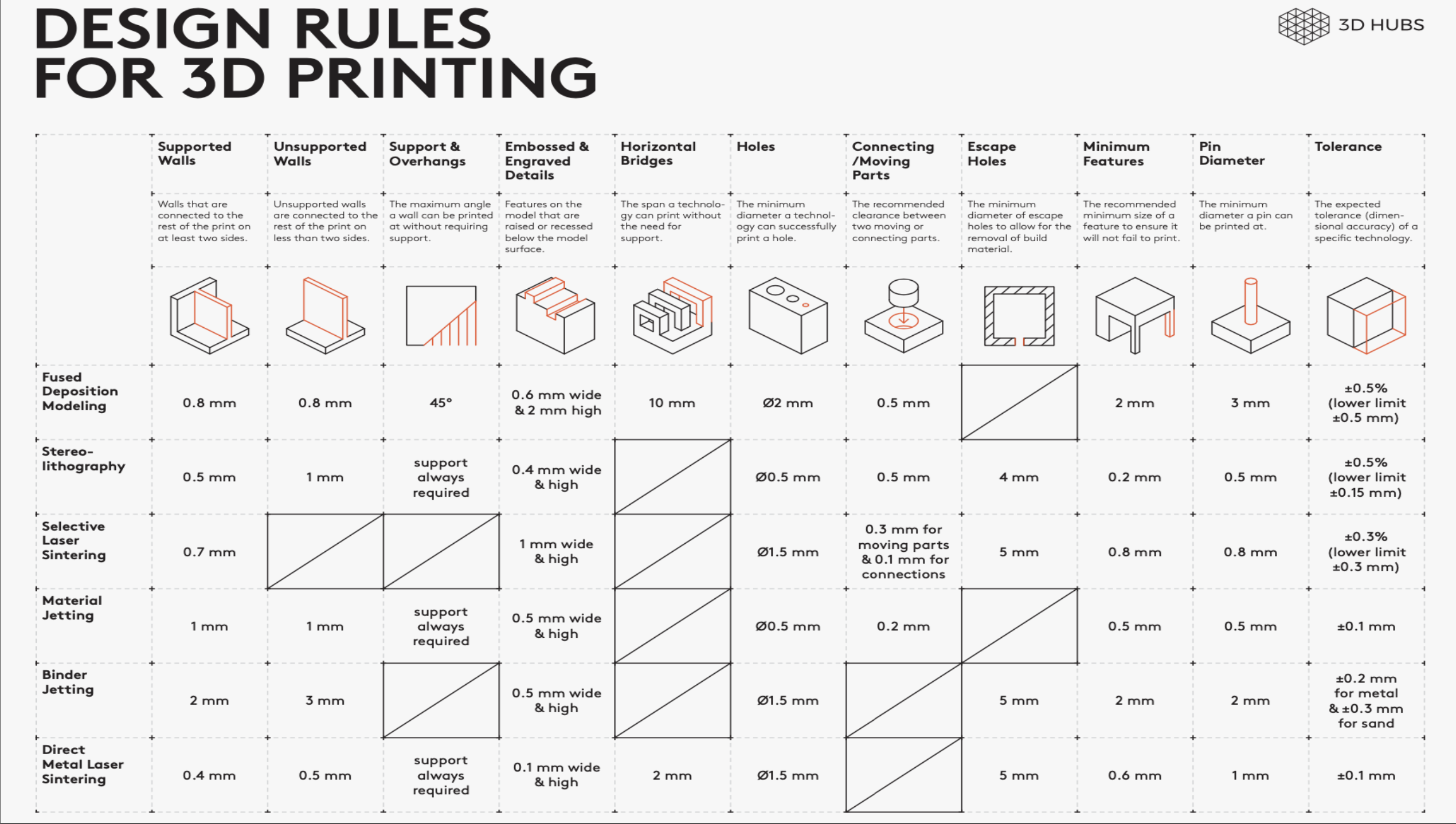

The following can give you some basic guide to choice which kinds of 3D printing meet your requirment

Reference from 3D hubs

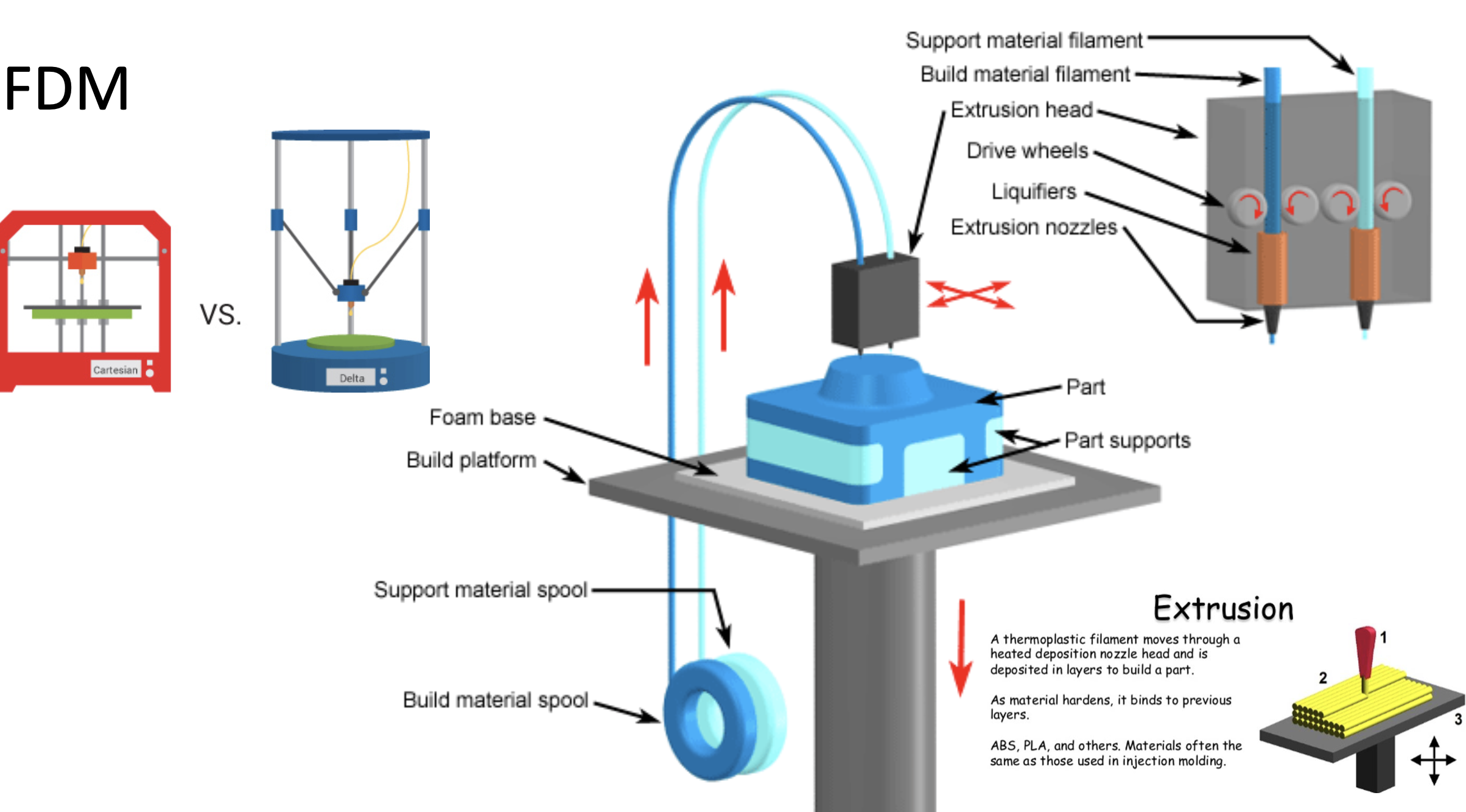

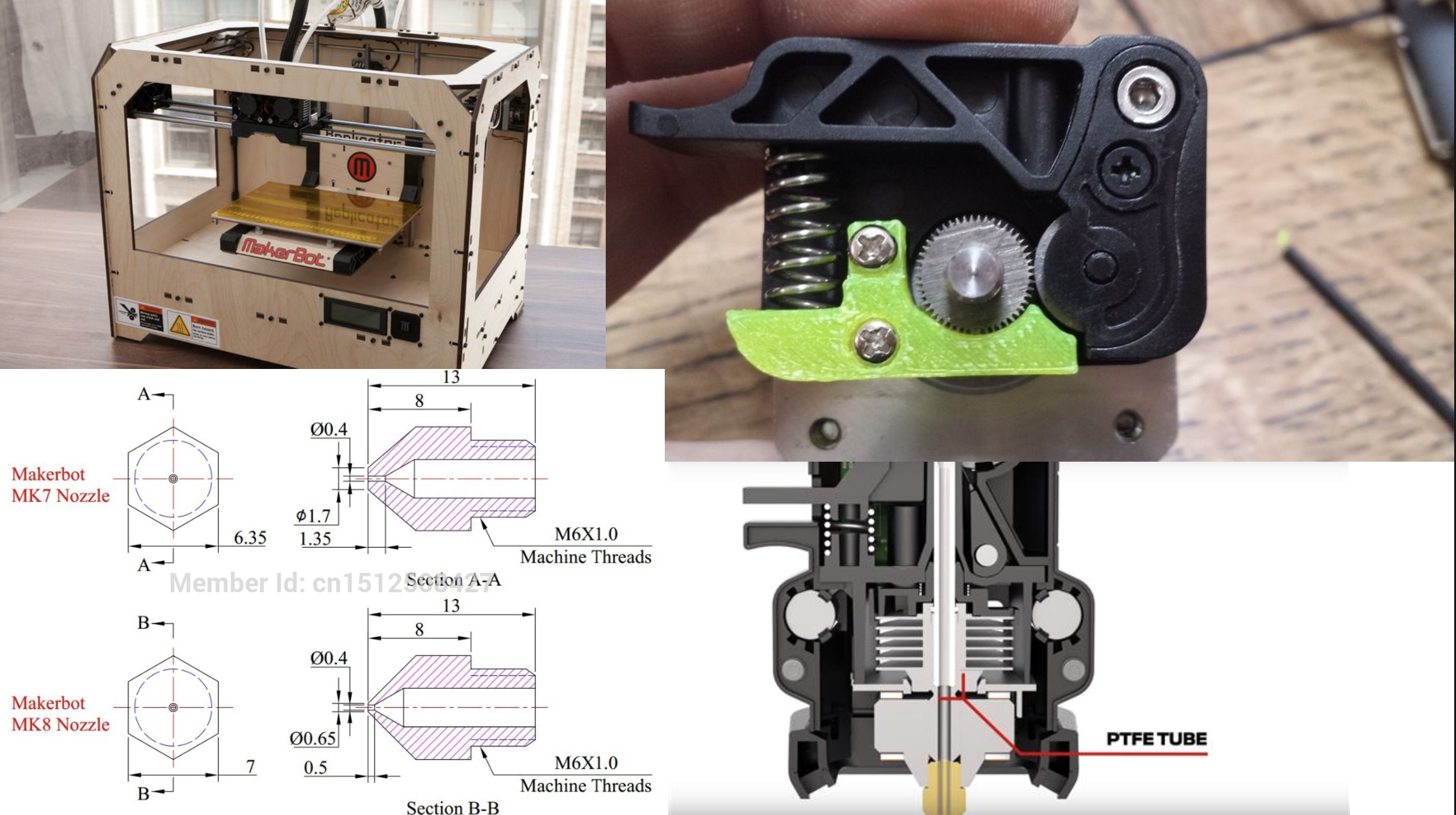

3.1 Material extrusion(FDM)

Material is selectively dispensed through a nozzle or orifice

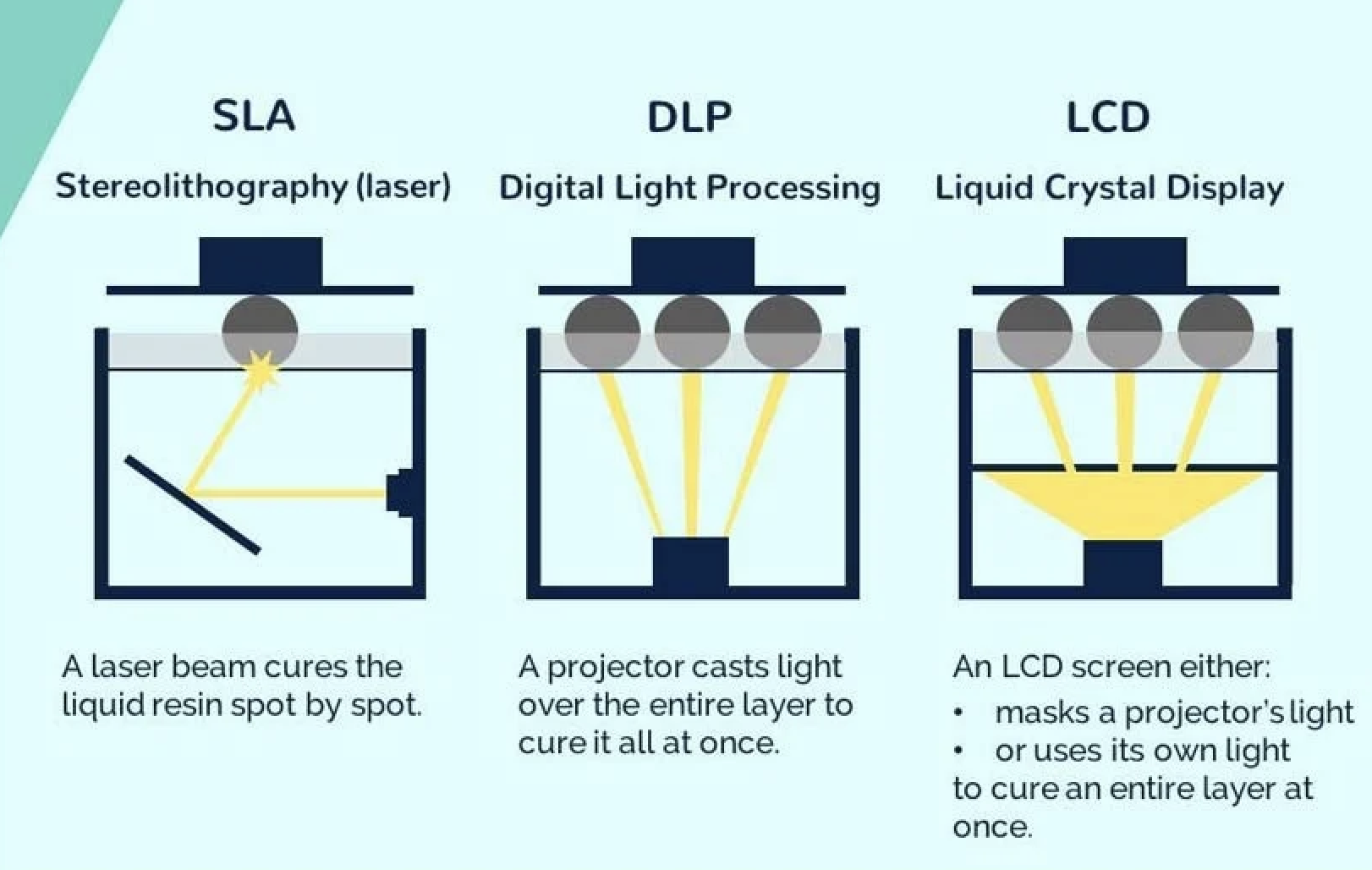

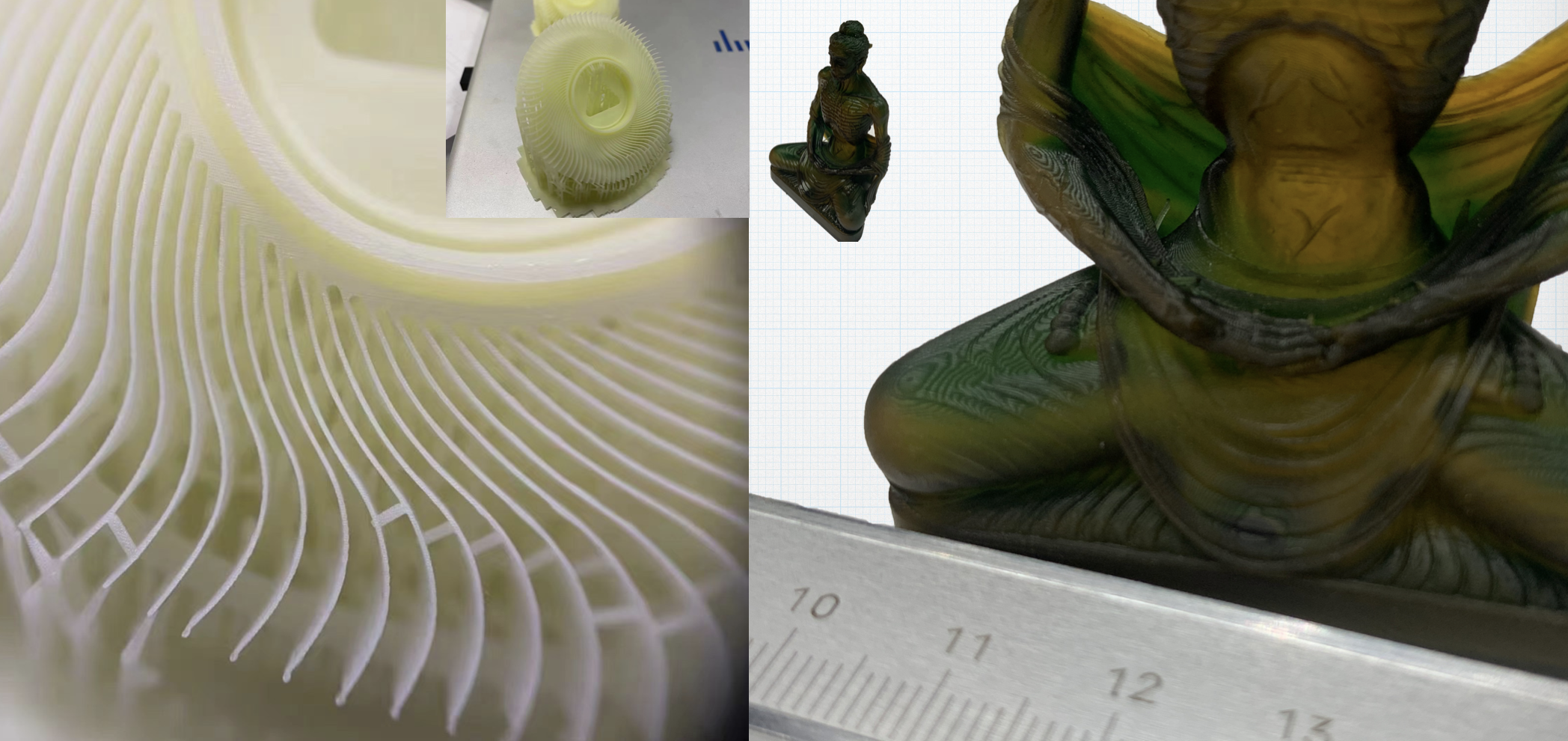

3.2 Vat photopolymerization(SLA,DLP,LCD)

Liquid photopolymer in a vat is selectively cured by light-activated polymerization

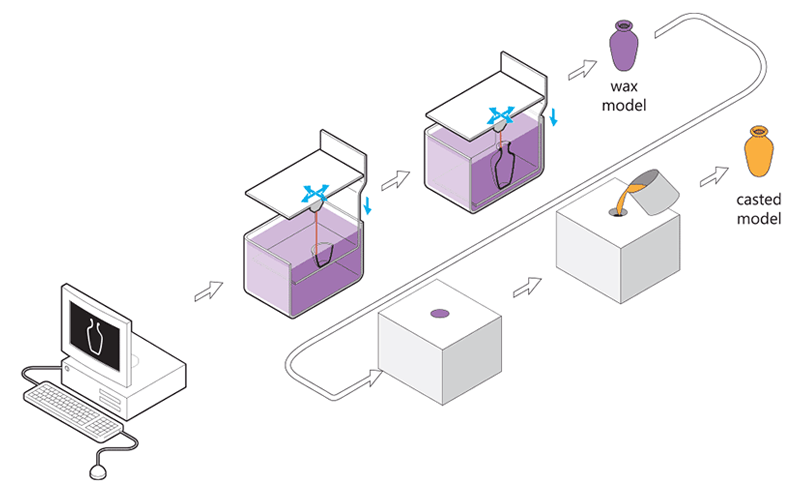

DLP 3D printing used in high precision model especial especial lost wax casting model for example jewelry.

DLP 3D printing used in high precision model especial especial lost wax casting model for example jewelry.

LCD 3D printing is a cheap method which use screen to solid resign.

LCD 3D printing is a cheap method which use screen to solid resign.

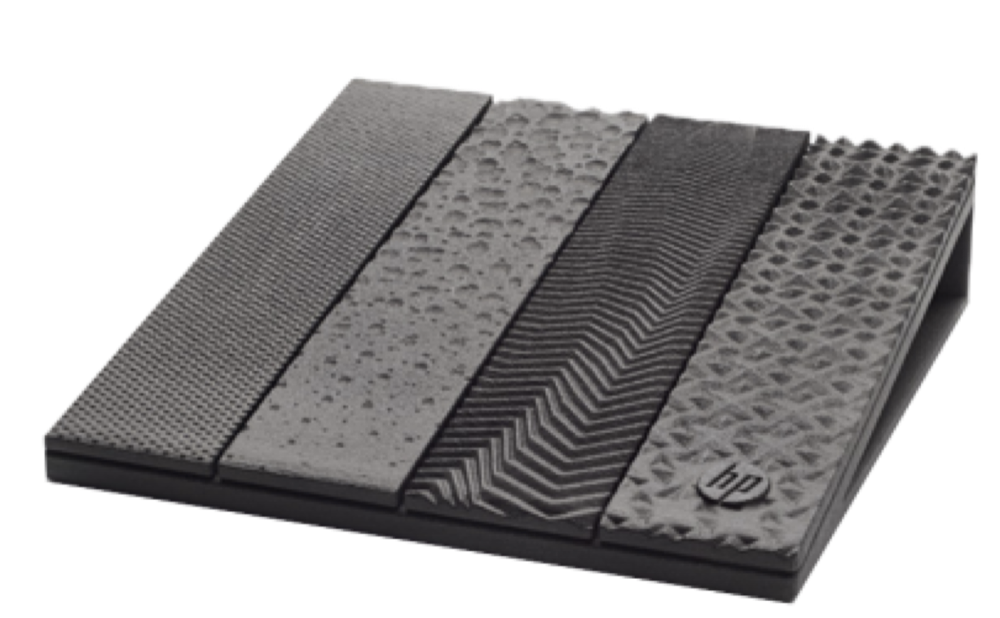

3.3 Powder bed fusion(SLS,SLM)

Thermal energy selectively fuses regions of a powder bed

3.4 Material jetting(MJ)

Droplets of build material are selectively deposited

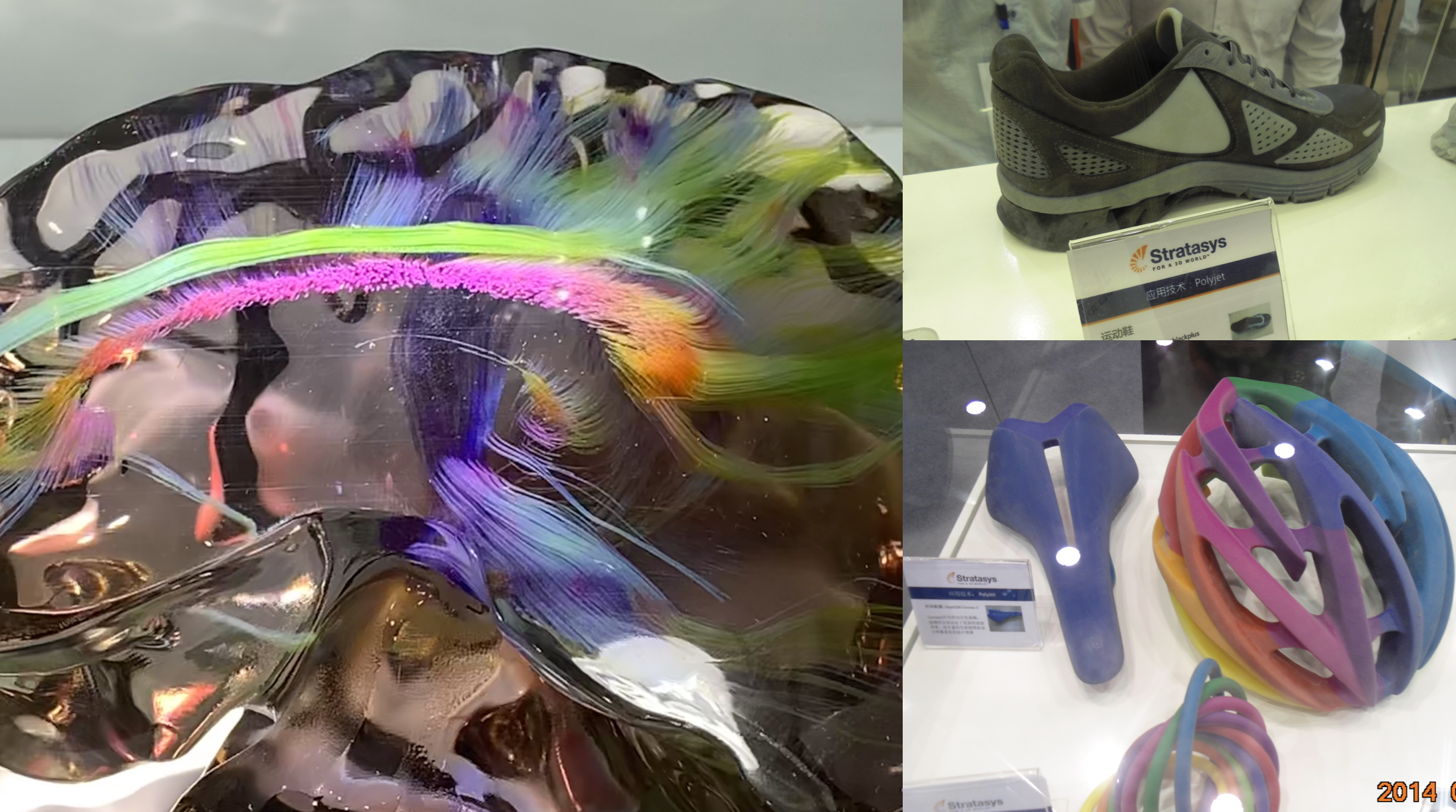

3.5 Polyjet

4. 3D printing VS Traditional Manufacture

When we process one part ,normally we can choice additive technology(3D printing) ,subtractive technology(For example CNC, milling, lathe, Wire cutting) or formative manufacturing technology(Injection molding). They have their own advantage and disadvantage.

- Cost:

- Additive technology has advantage in prototype test or Customized part;

- Subtractive technology is typically more economical when make parts in the 100 pcs;

- Formative manufacturing has advantage in mass production.

- Geometry

- Additive technology can have complex geometry(inner flow channel, cavity, thin wall, and rib );

- Subtractive technology has require in geometry. For example CNC can't process inner flow channel which bend by itself;

- Formative manufacturing has more require in geometry. For example injection need draft angle in molding. In addition injection molding can't make complex inner flow channel.

- Material:

- Additive technology has require in material ,every machine would Specified material. For example FDM 3D printing normally use ABS and PLA. So it would influence the effect of part;

- Subtractive technology can process almost every solid, for example metal, plastic ,wood, etc;

- Formative manufacture could process material mainly in plastic.

- Quality: Normally ,subtractive technology is similar with formative technology, and they are better then additive technology

- Size:

- Additive technology has requirement in part size ,the small the better;

- Subtractive technology and formative technology 's size could much bigger than additive technology

5. Design rule

6. Tendency

7.Reference

- Makerbot build Thingiverse which is the biggest open source 3D printing model community in the world. Maker can download the model they need. It lows down the hardness in design.

- Ultimaker provide Cura which is easy to set 3D printing parameter

- Bambambulab build MakerWorld

- Cults3d