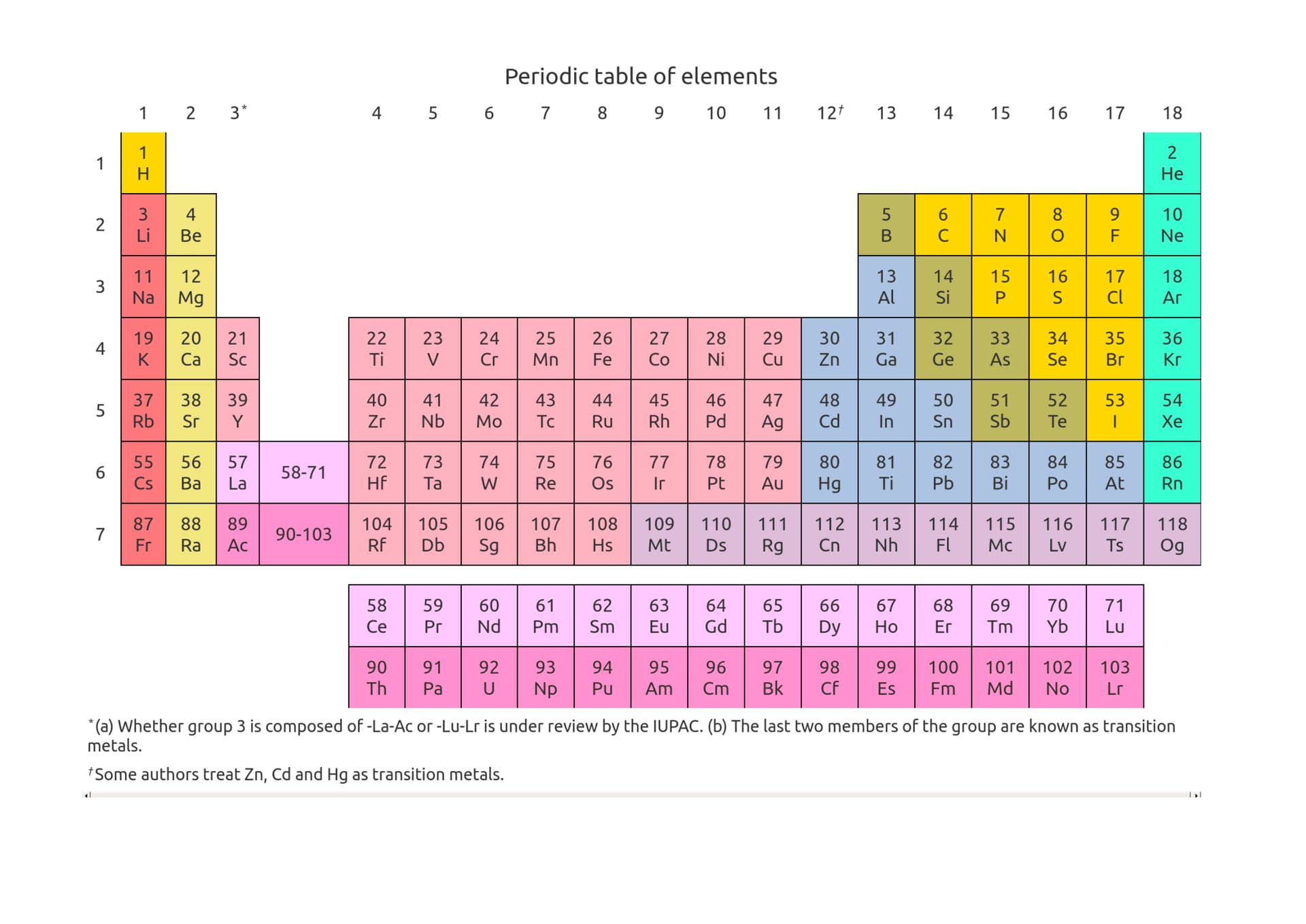

1.Periodic Table of the Elements

2.CMF

2.1 Color

There are a few color systems that have been developed over the years to ensure that nothing is lost in translation between designer and manufacturer.

The most common tools for achieving agreement on color standards are the Pantone Matching System, and RAL Color System . US-based designers and engineers tend to use the Pantone Matching System, while RAL remains popular in parts of Europe. Manufacturers that work with global customers will typically be familiar with both systems.

CMYK

Process colors utilize a limited number of inks, such as cyan, magenta, yellow and black (CMYK), applied in different ratios to create a variety of colors. Process colors are generally used when color accuracy or range is less critical.

Process colors utilize a limited number of inks, such as cyan, magenta, yellow and black (CMYK), applied in different ratios to create a variety of colors. Process colors are generally used when color accuracy or range is less critical.

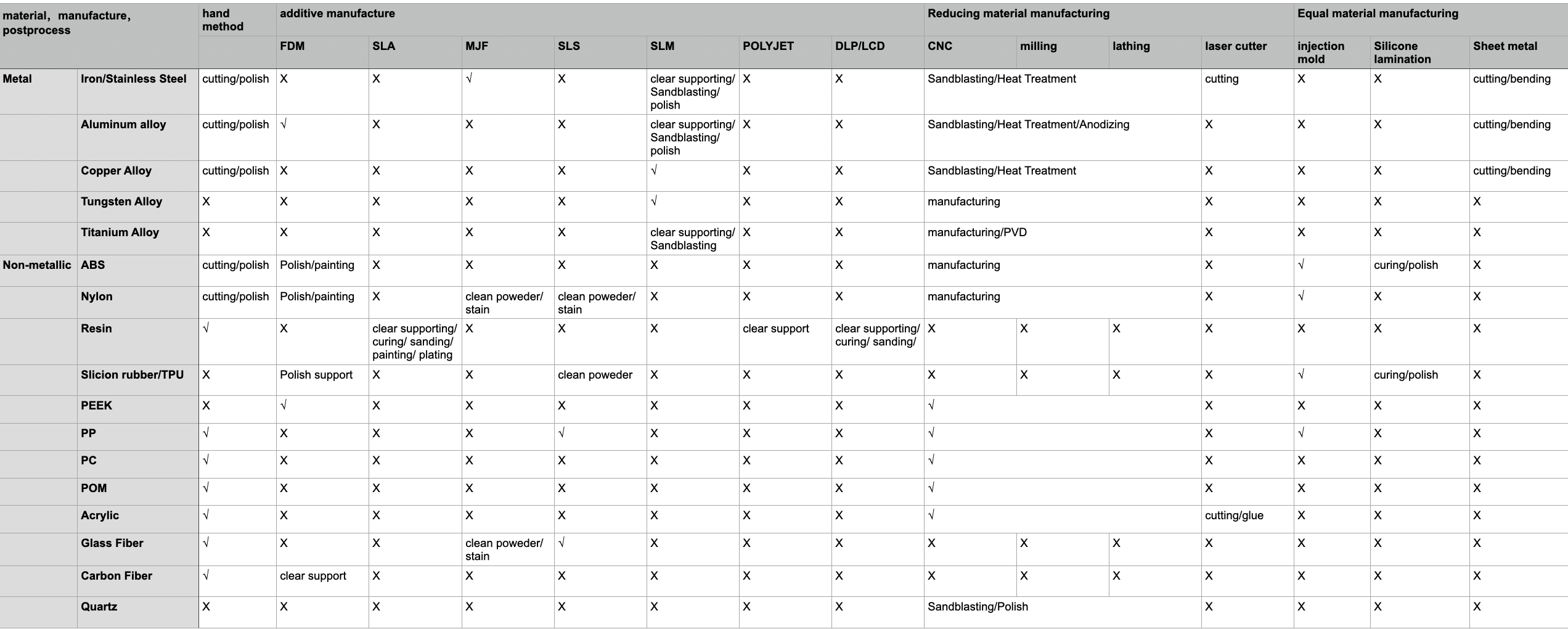

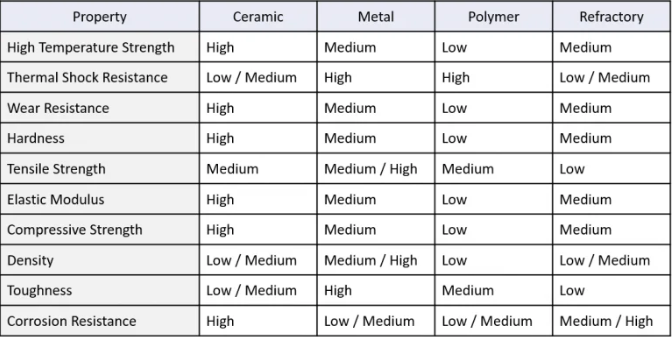

2.2Material

| Material | Common Uses | Subcategories | Advantage | Disadvantage |

|---|---|---|---|---|

| Metals | This material is typically shiny and lustrous. It is malleable and an excellent electrical conductor | Aluminum Copper Tin Steel Bronze etc |

Durable High-quality results Heat and cold resistant |

Can be challenging to work with Higher cost Difficult to source |

| Polymers | At the molecular level, polymers are comprised of a large number of similar units and can be either synthetic or natural. | Polyethylene Nylon Teflon Cellulose Rubber |

Easy to source Inexpensive Simple to work with |

Lower-quality results Less durability Limited heat capacity |

| Ceramics | These are nonmetallic materials―typically clay, but not always―formed using high heat. | Glass Cement Clay Porcelain Stoneware |

Lightweight Robust electrical insulation Inexpensive |

Dimensional tolerances can be inconsistent Cracking is possible Processing can be challenging |

| Composites | This involves combining two or more disparate materials to create a new, unique material. | Concrete Plywood Fiberglass Paper Reinforced plastics |

High durability Customizability Affordability |

Can be bad for the environment Repair is challenging May require special handling |

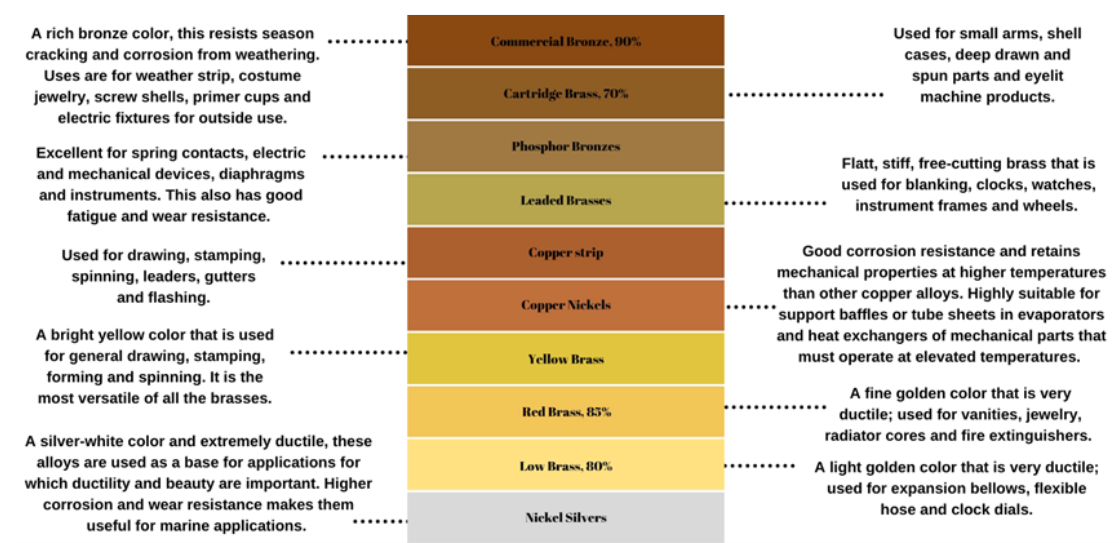

Metal

| Serial | Main alloying elements | Principal | Example application |

|---|---|---|---|

| 1xxx | 99.xx% pure aluminum | High electrical and thermal conductivity, excellent corrosion resistance. | Electrical conductors and chemical processing equipment. |

| 2xxx | Copper | High strength-to-weight ratio, low corrosion resistance | Truck wheels and suspensions, aircraft fuselage, and wings |

| 3xxx | Manganese | Moderate strength and good workability. | General sheet work, recreation vehicles, electronics. |

| 4xxx | Silicon | Low melting point and thermal expansion, high wear resistance. | Welding wire and brazing alloy, architectural applications, forged engine pistons. |

| 5xxx | Magnesium | Moderate-to-high strength, good weldability, good corrosion resistance. | Appliances, automotive parts, marine components. |

| 6xxx | Silicon and magnesium | Medium strength with good formability, weldability, machinability, and corrosion resistance. | Structural applications, architectural extrusions, recreational equipment. |

| 7xxx | Zinc | Moderate-to-very high strength. | Airframe structures, mobile equipment, high-stress parts. |

| 8xx.x | Tin | Low friction. | Bearing and bushing applications. |

| Element | Effect | |

|---|---|---|

| Nickel | 2-5% nickel content increases toughness12-20% nickel content increases corrosion resistance | |

| Manganese | 0.25%-0.4% manganese content with a bit of sulphur can lessen brittlenessOver 1% will increase hardenability | |

| Silicon | 0.2-0.7% silicon content increases hardenability and strength2% silicon content | increases yield strengthHigh percentages will also give magnetic properties to the alloy steel |

| Chromium | 0.5-2% chromium content increases hardenability4-18% chromium content increases corrosion resistance | |

| Boron | 0.001-0.003% boron content increases hardenability | |

| Copper | 0.1-0.4% copper content increases corrosion resistan |

Polymers

Ceramics

Composites

Finish

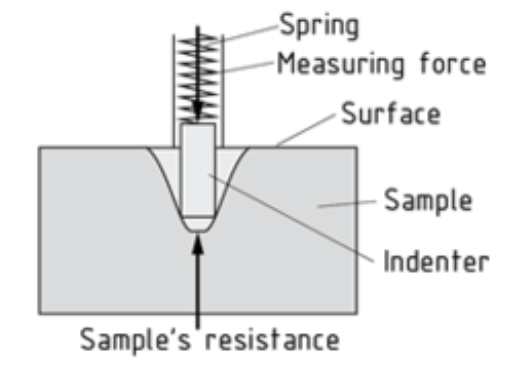

3.Performance

Other method

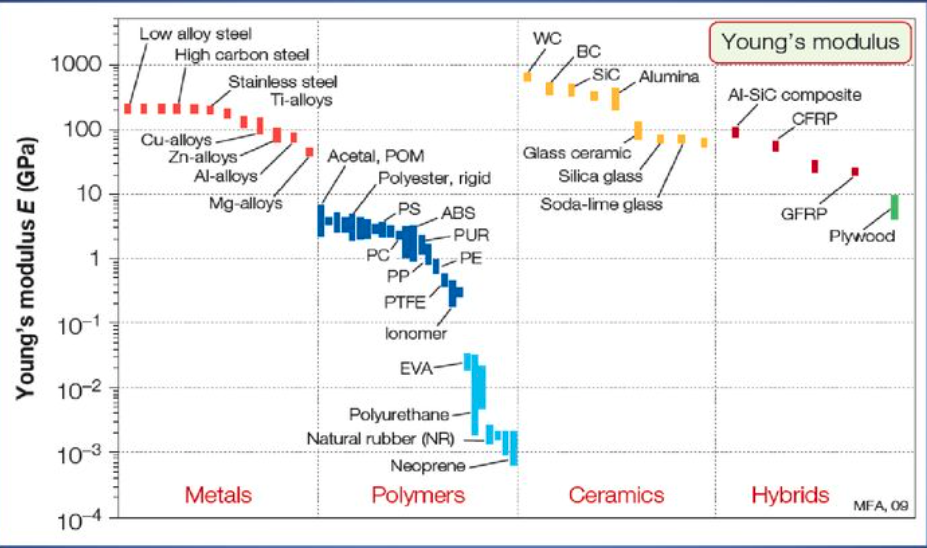

Strengh young module

Strengh young module

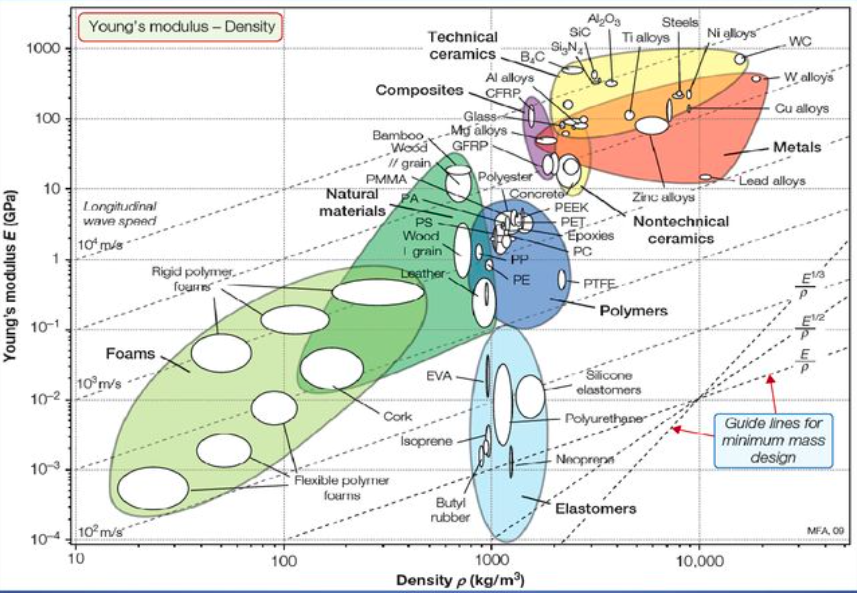

Young-Density module

Young-Density module

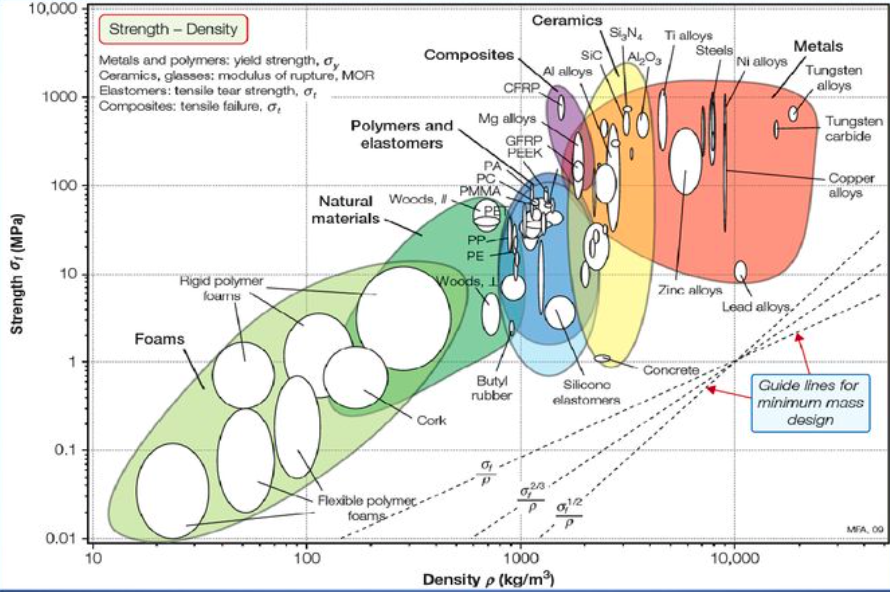

Strength-Density module

Strength-Density module

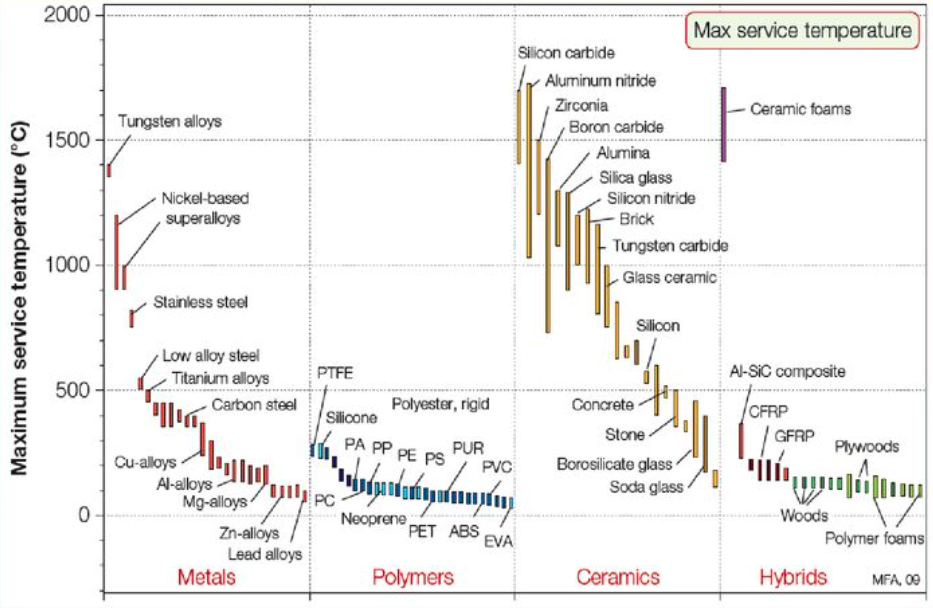

Max service temparture

Max service temparture